WARNING: This is a VERY long post. And I had to split it into even a third part. It's a very big project, so that's just how it has to be. So grab a cup of coffee or a beer or have a seat on the John. You might be here awhile. Below is a simple table of contents so you can jump around as you please, or come back to where you left off.

- What

- Why

- How

- Bill of Materials

- Getting started

- Water tanks

- Swamp cooler (optional)

- Floor

- Walls and door

- Roof

- Straps

- Finish

What did you do?

I built a hexayurt. Well, it has eight sides so it's an octayurt. But that isn't counting the nine roof panels and single floor panels. So is it an octodecayurt? Then again, regular hexayurts have 12 panels and we don't call them dodecayurts.[1]But maybe we should.

Source: https://faculty.kutztown.edu/schaeffe/Tutorials/General/Polygons.html

Source: https://faculty.kutztown.edu/schaeffe/Tutorials/General/Polygons.html

I built a yurt. I don't know what to call it but it has wheels! It was pretty cheap too, and it's light enough that I can push it around the yard with one arm to put it away. It's also got some additional features that my last yurt didn't have. These include fresh water tanks, a 12 volt RV pump, a swamp cooler, and a shower stall.

What? So you built a camper trailer then?

No. Well, yes. But it's a yurt at heart is the point. But very good question for the "what" section! A picture is worth a thousand words, so below is what it looks like:

|

| A picture of a thing you can learn to build by reading the words on this page. |

To compare, my dad had an old 1970 Ford Class C RV. We took it to Burning Man a few times and it was nice, but unless you ran the A/C it was much hotter than an un-cooled yurt. Plus it got 8 miles per gallon, and only did about 55 mph. It also needed a lot of care and maintenance. He was a mechanic and enjoyed that sort of thing. I'm not. And I like yurts. He never got a chance to try a yurt, but I think he would have liked them too.

|

| It's big, it's old, it's BOLD![2]Source: Big + Old - ig |

So I've had an RV, and... well... let me tell you - This is basically a minimalist camper trailer/RV, yeah. But it's still a yurt!

Why did you do this?

Well, most of that is outlined in Part I of this post. Some of it is outlined above. Yurts are great. RVs are great too. They are both great at different things. If we could only get them to breed...

Well, they didn't breed.[3]*citation needed* But let's outline the problems below:

Yurt issues:

Yurt issues:

| Cargo space used: | 32 cubic feet (too much!) |

| Setup/teardown time: | 30 minutes, up to an hour in bad weather |

| Minimum rain to flood: | 0 inches (if you don't seal it) |

| Packing efficiency: | Less than :( |

RV issues:

| Top speed (cheap RV): | 55 mph |

| Price (fast RV): | $5000 + |

| Gas mileage (most RVs): | < 13 mpg |

| Maintenance: | Usual vehicle plus normal home. |

| Cooling: | Requires generator (which demands gasoline and emits sound and smells in exchange for what it provides) |

| Weight: | Typically very heavy. |

We also had a some interesting additional (and perhaps not so feasible) ideas for the project. So let's make a quick summary of what we hope to accomplish here. We'll even throw in the "crazy-pill ideas."[4]Source: Colorful little capsules?

Goals:

| Top speed (towed): > 55 mph | > 55 mph |

| Price: < $1000 | < $1000 |

| Gas mileage: | > 13 mpg |

| Maintenance: | 3rd grade level[5]Requirements: Scissors, tape, ask your dad to work the power tools. |

| Setup/teardown time: | < 10 minutes in any weather. |

| Cooling: | No generator required. |

| Weight: | Towable via a Subaru Forester (or similar). |

| *Packing efficiency: | > 100% (physics be damned!) |

| *Cargo space used: | < 0 (should provide MORE cargo space) |

| *Minimum rain to flood: | > 10 inches |

| *12 volt lighting: | Yes |

| *Swamp cooler: | Yes |

| *Shower stall: | Yes |

*Denotes crazy-pill idea

Awesome. That looks like a great list of things to have. I think that about does it for "Why."

And how did this happen?

Surprisingly uneventfully (save for losing a couple of foam panels off the trailer right after I bought them - one was fine but one got smashed and used for scrap). I've gotta be honest, most of my projects have snags. I don't know about you, but I expect it. Two or three trips to the hardware store isn't out of the ordinary for a run of the mill project. When I'm doing something this ridiculous, I expect many things to go wrong. Heck, I wasn't even 100% sure this was going to work when it was finished! I estimated the drag[6]Which is the force pushing backwards on the trailer

due to air resistance. using a few different methods. A couple of them yielded an estimated 1000+ lbs of drag at 75 mph! Wicked![7]Data suggests it's actually about 313 lb, which is

about THREE times more than Scooby generates

by himself at that speed. I believed it would work, however, because of the experience I had with my prior yurt. I figured something that could take 90+ mph wind when built with folding joints should be able to handle road loading just fine if built with rigid joints. So I brainstormed some ideas to hold the whole thing down to the trailer, made sure the screws I used would keep it there, and got to planning.

due to air resistance. using a few different methods. A couple of them yielded an estimated 1000+ lbs of drag at 75 mph! Wicked![7]Data suggests it's actually about 313 lb, which is

about THREE times more than Scooby generates

by himself at that speed. I believed it would work, however, because of the experience I had with my prior yurt. I figured something that could take 90+ mph wind when built with folding joints should be able to handle road loading just fine if built with rigid joints. So I brainstormed some ideas to hold the whole thing down to the trailer, made sure the screws I used would keep it there, and got to planning.

That planning was very key here. And I'm betting it is the reason it went so much smoother than I would have thought. Because of the nature of this project, I was forced to plan ahead above and beyond normal requirements. You see, I had to take the trailer to pick up the large supplies from the hardware store. Since it was my only trailer, I was going to have to tear it down to bare minimum for the build. It would have been difficult at that point to go get more big stuff. So I had to make sure I had all of the supplies on hand for each section of the build!

Based upon that, we should probably plan out your build! I'm going to put a bill of materials (also and hereafter called the BOM) below, but that will be for the 6' stretch based design that I used, with a center strip added to widen it to legal limits. If you'd like to create your own variant, please do! Just use this as a guideline. And also, if I've forgotten anything - PLEASE let me know in the comments. You can even swear at me. Though I reserve the right to swear back if you do that. But if you are super duper nice, I'll give you credit for your help!

Base Setup

| Item | Cost | Quantity | Total |

| Harbor Freight Trailer | $250.00 | 1 | $250.00 |

| 8 foot 2 x 4 | $2.77 | 15 | $41.55 |

| 10 foot 2 x 4 | $3.52 | 2 | $7.04 |

| 12 foot 2 x 4 | $4.56 | 2 | $9.12 |

| Bifilament tape (60 yd roll) | $27.99 | 3 | $83.97 |

| Aluminum tape (50 yd roll) | $8.99 | 3 | $26.97 |

| Pipe strap (100 foot) | $15.54 | 1 | $15.54 |

| 2.5" deck screw 50 pack | $4.94 | 1 | $4.94 |

| 4" deck screw 50 pack | $6.75 | 1 | $6.75 |

| 4 x 8 x 1/2"sheet plywood | $14.98 | 3 | $44.94 |

| 1.5" thick RMax | $25.98 | 11 | $285.78 |

| 3.5" lag screws | $1.25 | 8 | $10.00 |

| 3.5" eyelet screw | $1.10 | 4 | $4.40 |

| Three-point door latch | $23.10 | 1 | $23.10 |

| Jack stands | $9.37 | 4 | $37.48 |

| Roof vent | $15.00 | 1 | $15.00 |

| Rubberized roof coating (5 gal) | $45.00 | 1 | $45.00 |

| Total: | $945.96 |

Electric kit

| Item | Cost | Quantity | Total |

| LED strip | $13.29 | 1 | $13.29 |

| Wire | $15.95 | 1 | $15.95 |

| 12V box (optional) | $39.99 | 1 | $39.99 |

| Running lights (optional) | $9.99 | 1 | $9.99 |

| Porch light (optional) | $11.87 | 1 | $11.87 |

| Total: | $91.09 |

Running water kit

| Item | Cost | Quantity | Total |

| Fresh water tanks | $57.95 | 2 | $115.90 |

| 1/4" NPT nipple | $3.00 | 2 | $6.00 |

| 50' 3/8" ID vinyl tubing | $14.00 | 1 | $14.00 |

| 12V RV pump | $29.99 | 1 | $29.99 |

| 1/2" PVC x 10 feet | $1.79 | 2 | $3.58 |

| 50' 1/4" fresh water tubing | $9.99 | 1 | $9.99 |

| Gray water tote | $10.00 | 1 | $10.00 |

| Shower curtain and hooks | $5.00 | 1 | $5.00 |

| Sink (optional) | $27.99 | 1 | $27.17 |

| Tank valve (optional) | $21.05 | 1 | $21.05 |

| Tank valve fittings (1/2" npt) (optional) | $3.00 | 3 | $9.00 |

| Total: | $251.68 |

Swamp cooler kit

| Item | Cost | Quantity | Total |

| Swamp cooler tote | $10.00 | 1 | $10.00 |

| Swamp cooler fan | $23.57 | 1 | $23.57 |

| Swamp cooler pump | $9.99 | 1 | $9.99 |

| Float valve | $7.50 | 1 | $7.50 |

| Total: | $64.05 |

Solar kit

| Item | Cost | Quantity | Total |

| Solar panel | $112.99 | 1 | $112.99 |

| Solar charger | $18.99 | 1 | $18.99 |

| Solar panel connectors | $5.88 | 1 | $5.88 |

| Total: | $137.86 |

That's a total of $945.96 for the basic setup! Not too shabby. $1490.64 with all of the optional equipment. Of course, this will be your creation so feel free to design it to your liking :)

Now, attach all of these things to each other, and you are done!

Okay, okay, do it in the right order and you are done!

Alright, while you are here, I'll show you the way I did it. But before I do, just a quick note:

I can not officially recommend that anyone take one of these on the freeway or even out of their driveway without consulting a qualified individual to inspect it for roadworthiness. I am not that guy. Sure, I did it for my own design, but I took many careful slow trips leading up to pulling it on the freeway. Between each one I inspected the joints carefully, and made sure nothing was shaking loose. I put a lot of time and effort into this, and I didn't want to lose what I had built. Even more than that, I didn't want to have something fly off and cause an accident or otherwise hurt someone. So please, please be careful. Don't use my recommendations as a "go-ahead" to just build and drive. Remember, (as far as I know) this is uncharted territory. This vehicle is the first of its kind. Yours may very well be the second. Treat it as such, and respect the dangers involved.

Thanks for reading that. I mean it. If we are going to make the world a better place, we have to do our best not to accidentally make it a worse one. Not to say that building a camperyurt makes the world a better place. But I believe the open-source community does, and this is a part of it. So I guess one could say we are contributing.

Now let's get started: First, you'll have to assemble your trailer from Harbor Freight. You could certainly use any other trailer you want, however I'm going to assume everyone is building from the BOM above. Below is mine after stripping it down.

|

| The skeleton of adventures past. |

Very Important Protip: If using the Harbor Freight trailer, please disassemble and re-grease the bearings on the axle before use. It seems that there have been a few cases where folks have gotten trailers without proper lubrication. It's a 10 minute job and might save you several hours on the side of the road. Other than that, there's not much that can go wrong with this trailer.

To continue, this is a very small trailer. It may look a little silly throughout the build. It may also look silly after you are done with it. But if you take good care in building, it works! Depending upon whether or not you are installing fresh water tanks underneath the floor will determine how critical the next part is, as well as what measurements you will use. Rather than give specifics, I'll go over a general guideline of how I mounted the tanks, since not everyone will use the same trailer and tanks. If you use the same items I did, you'll come up with the same design if you follow the instructions!

Using the lag screws, mount an 8 foot long 2 x 4 at both the front and rear of the trailer, centered of course. Next, mount a 4 foot long 2 x 4 in front of the rearmost one, to space the tank away from the frame rails. Mount the fourth 2 x 4 as close to the front of the little fenders as you can get. And finally, mount the fifth and sixth 2 x 4's exactly the width of the short side of the tank (plus about a quarter inch wiggle room) forward of the center and rear boards. Whew - if that's a bit confusing hopefully it will become obvious with some of the below pictures.

|

| It's a start. |

When you are done with that, you can install the water tanks. To do so, cut a section of plywood to match the bottom of each tank. This is to protect the bottom of it from road crud. With my build, I screwed the plywood to some 2 x 4s as well, but I'm not convinced that was necessary. Either way you do that, once finished you'll need to measure the height (H) and short width (W) of the tank with whatever wood goes under it. Cut three or four straps to the length of (H + H + W + 3 + 3) inches. Spacing the straps evenly, extend three inches of each strap over the 2 x 4 that will sit at the rear edge of the rear tank. Lay the straps across the gap, and repeat the 3 inch overlap on the other side. Lower an EMPTY tank between the boards and check the height. It should be dead on, but if it's not, adjust it. Once you get all of the straps right, you can add some water to make sure it doesn't sag too much when the straps pull tight. If it does, adjust the setup as needed. I recommend adding an extra deck screw (or two, or three) to each side of each strap once everything is set. Repeat this process for the forward tank using the appropriate boards.

|

| Tank 1 installed. Wheeeee! |

|

| Tank 2 installed. Wheeee-heeee! |

Because I wanted to ration my water as well as have it pumped inside, I used some scrap wood to make a little mount for my tank selector valve (totally optional) and also the RV pump (totally rad). You can see it in the next photo, to the left (our left) of the front tank. Apologies that I don't have a better picture right now. If you've never used an RV pump, they are pretty simple and very cool.. They pump the water up to a set pressure and then shut off to save battery. Without any leaks, you can theoretically leave them on all the time! I turn mine off when not in use though, in case a leak develops. Assuming you are using the vinyl tubing (or similar), make sure to get a 35 PSI pump and not something that's going to blow out your plumbing. I'm using the one in the BOM.

I routed the tanks to the pump through the tank selector valve, but you can use a tee fitting if you'd like. The selector valve allows me to keep one tank just for showers, and another just for drinking. Or share it with camp mates. But it really isn't needed. As for the vinyl tubing, it provided more than enough flow with the pump. Another optional step is to install garden hose spigots on each tank to get water when you are outside of the yurt. I also use those to fill them up using ahose (a CLEAN hose is always used) and also to allow camp mates to share my water. When the trailer was in its prior configuration those spigots were easier to access. You may consider a length of tubing and a better mounting location, but that's your call. You will have to find a way to fill up your system though one way or another.

I routed the tanks to the pump through the tank selector valve, but you can use a tee fitting if you'd like. The selector valve allows me to keep one tank just for showers, and another just for drinking. Or share it with camp mates. But it really isn't needed. As for the vinyl tubing, it provided more than enough flow with the pump. Another optional step is to install garden hose spigots on each tank to get water when you are outside of the yurt. I also use those to fill them up using ahose (a CLEAN hose is always used) and also to allow camp mates to share my water. When the trailer was in its prior configuration those spigots were easier to access. You may consider a length of tubing and a better mounting location, but that's your call. You will have to find a way to fill up your system though one way or another.

|

| Freshwater plumbed and ready. |

At this time, if you are installing a greywater tank and swamp cooler, you'll want to mount them in the remaining gaps. I picked up some cheap totes that would fit. While I can only hold 10 gallons of greywater, I normally just use my old evaporation pond to clear the tank each day. Anything leftover stays in the tote. If you intend to travel with a lot of greywater, you might want to source a proper tank. I tried to, but they are pricey. So I used a tote. I did fill the tote up and take it on the road with zero issues, but it's not something I think I want to officially recommend. It's more than enough to support a couple of gallons that don't quite get evaporated, however.

If you still wish to use a tote, here's how I installed mine. I cut a hole and installed a drain fitting into the bottom using some shoe-goo. Then, I hung it with straps as I did the freshwater tanks. I didn't use a plywood bottom for the tote though since it sat a bit higher up than the others. Later on I joined some 3/4" irrigation tubing together from the various drains in my floor, and plumbed them to the tank. I left a hose bib and cap on there to drain it to my evaporation pond. One thing I did learn however is that I should have used a larger diameter pipe to get water to and from it, as the 3/4" tube got plugged by the residue left in it while it sat for a few months. I'll likely summarize a good solution in the next post, but I have to figure that out first. Meanwhile I just blast the drain out with the hose to prep for a trip.

As for the swamp cooler, I screwed lid to some strapping, and added shoe goo to keep it stuck. The latches on this tote are capable of holding it tightly to the lid without any support. I put a drain plug in the bottom so I never have to travel with any water in it (which might break the latches). The tote is filled through a float valve, so it only ever gets a few inches of water in it anyhow. So far so good. I'm sure there are even more clever ways to do this stuff, and I hope to see some folks being inventive! I'll briefly describe the principles behind swamp coolers next, but I will leave the full design specs for a later post (as I'm still tweaking things a bit). Feel free to skip the next box if you don't need to know about swamp coolers.

At this point, your creation needs a floor. All that stuff so far is pretty neat for sure, but it's useless without a floor. There are far too many holes, and nothing looks comfy to sleep on. Plus, you need SOMETHING to hold up the walls. So the next step is to build a floor. At least I think so.

How big of a floor can you make? The laws around here say you can't have a trailer more than 8' 6" wide. So there's an upper boundary. I've built a few 6' stretch hexayurts, but they are only about 7 feet across.[8] Source: http://www.appropedia.org/Hexayurt_playa For my personal yurt, I decided to go big or go home.[9]Ironically I did both since I was building a "go home."

Source: It is a home that goes. And it is big.*

*Does that mean I go big or go home with my big go home?

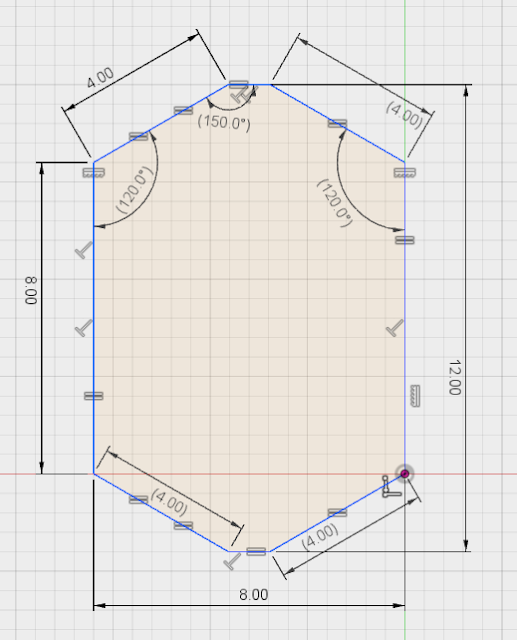

My my... How meta, once again. I decided on 8 feet wide, since that's the width of standard plywood sheets (and also to err on the side of caution). The length of the 6' stretch is appropriate for the trailer, so I decided to keep it. Below is the floor plan.

That's just what I used. Your trailer might be longer, and by all means, modify the design. But if you are going with the setup I used, just follow along :)

You can build this floor out of three sheets of 4' x 8' plywood. You only need to cut the corners off of two sheets as seen below.

The third sheet will go in the middle of these two. I wish I had taken a picture of the bottom of the floor, but I didn't, so I'll have to explain what I did.

I screwed the three pieces of plywood together to two 8' 2 x 4's, one on the left and one on the right. That held the whole mess together to work with. Next, I screwed a 12' 2 x 4 in the center to add a bit more support. Finally, I slid a 10' 2 x 4 on each side and screwed them on in-between the 8' and 12' boards. Together, these created the longitudinal support for the floor.

For lateral support, I used 8' 2 x 4's. I screwed them underneath the longitudinal boards to match the spacing of the boards on the trailer. This was needed for two reasons: One - I needed a bit of extra height to clear the fenders. And two - I wanted to be able to lift the entire yurt off of the trailer, if the need arose. The completed and installed floor is below. Again, apologies for not having pictures of the underside.

The floor is held onto my trailer via the longitudinal boards. I used lag screws to hold the pairs of 2 x 4's together. The only exception is on the four corners, where I used the eye screws instead. This was to create an anchor point to tie the whole mess down in case it got really windy (it's light enough that I worry the wind would push it around if it's empty). The floor itself was screwed on tightly to the 2 x 4's directly under it in the previous step (seriously, when in doubt use a ton of screws, they are cheap!), so nothing is going to go anywhere. Because I was worried slightly about the front end lifting up while driving, I wrapped some pipe strapping around the forward 2 x 4 stacks and the frame, and screwed them down tight. In retrospect, I don't think it was really necessary, but I wanted to be sure. Lag screws don't have the greatest tensile loading capabilities after all.

IMPORTANT NOTE: Before you climb onto your new floor you'll need to support the edges and rear with jack stands or something equivalent at this point. The structure will be sturdy, but sturdy won't stop it from tipping over! You've been warned!

Now that you have a floor, you'll need to add a border that's offset by the width of your RMax foam. I used 1.5" foam, and as such I measured and cut my boards accordingly. In addition, you'll want to decide if you want to make a shower stall, or add any ventilation. You can form the shower stall from 2 x 4's, and the ventilation from a hole.

Below is what my floor plan looks like. I put the door in the back so the so wind wouldn't screw with it while driving. Then, I made the decision to put the shower in the back near the door because if I was filthy and needed a shower, I didn't want to crawl over my clean bed to get to it. Another consideration is that we planned to keep a camp toilet in the shower stall, so popping in from outside to use it would be more convenient that way.

I put the drain for my shower in the middle of the shower stall. That turned out to be a mistake. The water tends to pool in the rearmost corner when I'm in the shower, so I ended up having to move the drain there. In retrospect that makes perfect sense. I just had a lot on my mind when I built it and didn't think of this. But since you are reading this, you've already thought of it. Neat!

The next step was to put on walls. A floor isn't completely useless without walls however. At this point you might be able to bring your sick dance moves to the floor! You've never danced like this before![10]Source: Milky chance. Except for the fact you put all of those 2 x 4s on top of it to trip up your dancers. Pity. Oh well, let's just keep going then.

The 6' stretch yurts I've built have 4' walls on the sides. This gives standing room in the very center, but just barely! Since I was going big, I wanted to be able to stand up in the thing. And also wave my arms around when changing clothes At Burning Man I have seen some of the tall yurts (with 8 foot walls). I think those are a little bit too tall, but I understand why they are built that way. The foam panels come in 4' x 8' sheets, so 8' is a natural height.

But what we are doing isn't natural, is it?

I was worried about drag while I towed this thing. I also needed a few 1' 0.86"[11]Still an unclean mess of a dimension.

Source: Ewww. strips to widen the classic 6' stretch design to 8 feet. I figured I'd cut those off the edges of the wall panels, and shorten the walls. Because I was cutting the walls down anyway, I decided to shorten it further to reduce drag.[12]Less height = less area, and since drag is

proportional to area, less area yields less drag. I chose 6 foot tall walls. Why? It sounded good at the time and gave me a decent door height. Would I do it differently if I did it over again? Yes. I'd probably cut them down to 5 feet to reduce drag a little more. But hindsight is 20/20, and my yurt is built and I'm not changing it at this point. So that's how these instructions will proceed. Feel free to work out your own design though!

After you decide on your height, cut all of your wall panels (if you are following my exact design, 8 full wall panels and two narrow ones) to whatever height you decided on. Next, you'll want to miter them to fit together a bit better. That means you'll want to angle the corners so that the panels meet at the appropriate angles. This is quick to do with a circular saw, but makes lots of foam dust. Below are the angles for the walls using the 6' stretch base with a thin panel in the middle:

Once you get that together it is relatively simple to add strips of tape to pop it up into its final shape. I'd do the aluminum tape work at this time, and in retrospect I might put some rubberized roof coating on while it is easy to do. I did use the house as scaffolding to do that step later, and while it worked it involved painting, climbing down, rotating, climbing up, painting, repeating those steps, and generally took a long time. So painting it on the ground MIGHT work better - then again it might not. You'll probably still have to add some roof paint later, but not nearly as much and it may be doable with a simple roller. Perhaps just make your own choice after reading the whole post. I don't wanna mess things up for you - you've come this far!

Once you get that built and taped, lift it up onto your walls. It should be light, and without wind you may not even need help. But help is good, so find it if you can. Pay your help in tasty food or beer. That last part is optional, but always appreciated I'm sure.

Once the roof was on the walls, the hard part was getting the tape on since I had to keep moving the ladder. If I did it again I might use the house as scaffolding to tape the roof on. If you do that and it works, great! JUST BE SUPER CAREFUL!

No time for rejoicing! You'll want to cover all of the exposed bifilament tape on the outside with aluminum tape! Remember how I said to do the walls before you did the roof? See how I didn't do it? Remember how I suggested to do the roof while it was on the ground and then I didn't do that either? Also remember how I said to ensure that you had plenty of daylight to do that step? And do you notice the shadows getting awfully long in this picture? Don't be like me! Don't end up doing it last minute in the dark!

Okay, did you get the tape covered? All good. Sweet. You can rejoice some! I rejoiced by repeatedly going in and out of the yurt. Then going inside and feeling like something neat had happened. Then going back outside and going in and out again. In retrospect it wasn't the greatest evening, but it sure felt good at the time. Still, there was more work to be done!

If you planned to take this on the road, as I did, you may be wondering what was going to keep all of that foam firmly attached to the trailer. After all, the tape didn't stick as to the wood as well as one would have liked. Additionally, roads are bumpy. I'd wager the different materials (foam and wood) would flex differently due to their differing weights and elastic properties. That flexing would make them inclined to separate from each other...

Separation would be bad. Though it would also be an awesome sight to see one of these come apart at 75 mph, it would also just be very bad. We don't want bad. Fortunately there's a simple solution! Grab your pipe strapping, and run three strips over your yurt (more if you have a different design that requires it). I did one longitudinally and two laterally. You'll see in the picture below. I also cut some squares from cheap ductwork sheet metal, and placed that underneath the straps where they went around the corners. This was to spread the load out so the strap didn't end up cutting into the foam. I held the sheet metal on using 3M spray adhesive just long enough to tighten the straps on. Again, this can be seen below:

You'll certainly want the straps to be tight, but not so tight as to crush anything. The self-supporting structure is strong, but we don't want to push it beyond what we need to.

Here is the method I used to get the straps on there with just the right amount of tension. First, I attached one end to a 2 x 4 using a deck screw installed at about 45 degrees. I left about 3/4" of thread length out. Then I tossed the strap roll over and pulled it tight with my bare hands. I added another screw at 45 degrees to the opposite side, but this time screwed it all the way in. The 45 degree angle caused the strap to tighten as the screw pulled in! Then, I went back to the other side and tightened the first screw carefully, and listened for crunching foam sounds. I heard no crunching, so this method seemed to work great! I ended up with a very tight strap and nothing getting crushed. Success! I added an extra deck screw straight in at each side for good measure (there are lots of holes to work with).

At this point I covered all of the straps with aluminum tape, to keep them from oxidizing mainly. I'm not sure if it was needed since I rubber-roof-coated everything, but at the time I was considering running it without the paint.

To install the optional roof vent (which will improve swamp cooler performance when your door is shut), I used 3M spray and some bifilament tape. I didn't cut the hole right away. I just stuck it on where I wanted it with the spray, and then taped it. After taping, I covered the bifilament tape with aluminum tape to protect it from the sun. Next, I measured where the center of the vent would be, went inside, and stabbed upward with a knife. So fierce. Then I sawed my way over to where the knife hit the roof vent. Next, I used the vent as a guide for the knife and ended up with quite a nice ellipse shape, just as expected. I finished the inside with some aluminum tape to keep the foam from crumbling and called that good.

At this time I decided to squirt some "Great Stuff" in the inner cracks of the panels (as mentioned earlier). This glues them together and creates a stronger joint. It also expands and provides a bit of tension to hold everything tight without wiggling. Keep in mind though, that it can expand and force your panels apart, so don't overdo it! I put a little in all of the gaps, more if there was a larger than normal gap, less if it was tight. I also did the gaps between the 2 x 4s on the inside and the foam panels.

Once the "Great Stuff" has dried, you'll probably want to cut off the lumps that squirt out. You can try to wipe it off as it initially squirts out, but you may come back and find even more of it. However you do it, you'll want to get rid of the lumps. Then you can add some bifilament tape on the inside for greater strength. I haven't felt the need to cover up the inside tape with aluminum tape since very little sunlight gets in there. So far, so good!

Before doing anything else, I wanted to test this thing on the road. The first steps were around the neighborhood, with a 25 mph speed limit. The next step was on the two lane road near my neighborhood, with a speed limit of 45. After each step I pulled over safely and looked it over. I was pleased to see nothing coming apart, but I resolved to wait until the next day for freeway tests. In the morning, I took it to the gas station and filled up. Then I took it on a segment of the freeway that had a 55 mph post. Since nothing went wrong, I continued to the 65 mph zone, and followed that to an area with a 75 mph posting. I was able to get Scooby (the Subaru Forester) up to 75, but just barely. He was really huffing at that speed! 65 is a much nicer cruising speed. I averaged 65 over the return trip to the gas station where I filled up and figured out my mileage. About 14 mpg. Not great, but not horrible. In it's prior configuration the trailer pulled me down to 17 mpg. It had a LOT less frontal area, so I'd say the shape of this yurt is reasonably aerodynamic for its size! Woo!

Below are some pics of the nighttime road test.

At this point, I coated both the inside AND the outside with rubberized roof coating.

So why not just run it naked? Woo! Naked!

Two reasons. The first is simple. Itt actually strengthens the foam a little bit, and allows it to deflect small rocks and bugs a lot better than the foil would by itself. The rubber coating doesn't tear quite as easily as the foil so things bounce off it more.

The second reason is longevity. On the playa if any tape started to peel, we'd see it and fix it. If this thing were to sit in my yard for a few months (which it does) and some tape started to peel, would I notice in time? The answer to that is most likely, no. And if I didn't, rain and dust would get under it and really start to mess things up. Then I'd have a ton of repairs to do before taking another trip. So I looked into the cheapest and most weather-tight way to seal everything up and keep the tape down. The roof coating seemed to be it. Also the reflective and radiant properties of the rubber roof coat match the aluminum of the insulation, so no performance degradation should be seen!

Great! But are there other options?

Yes, but they are EXPENSIVE. At least the ones I found. I'm open to suggestion though and will cite you here if you have anything that looks good! As for me, I looked into fiberglassing the whole thing. That would be wicked strong. But sorta pricey. I think I could do it for $600 to $800, but then I'd need a coat of paint to protect the resin anyhow, which leads us back to square one basically. Also a thin layer of fiberglass might be brittle and start to crack. So we'd need a thicker coat. But more fiberglass costs more money, and uses more resin. More resin also costs more money. I wanted this to be accessible to everyone. So "more more" money was sort of out of the question. But if you have the money and the skills, 'glass that sucka! Then paint it a nice fun (hopefully light) color!

Okay fine, but can't we get by without using the aluminum tape then? It's really a pain to put on. What if I plan everything out and paint over it right away before the bifilament tape gets any sun?

Perhaps. But I'm not 100% sure about it. I've found that unless the coating is REALLY THICK, light does penetrate the rubber roof coat. I have to assume some of the UV stuff gets through, and it might start to eat your tape. You could theoretically put a really thick coat on, but I had a heck of a time getting it thick on the vertical walls, even with multiple coats. I used my whole bucket too, and would have needed another entirely to even hope to get a thick enough coating. So my recommendation is that you use aluminum tape. But if you try it another way and it works, please let me know!

UPDATE: Testing has revealed that the rubberized roof coating I used doesn't stick super well to the bifilament tape by itself, but it sticks great to the aluminum tape. I'm not saying that there's no way to get rid of the aluminum tape - I just haven't found it yet.

To coat the outside, as I mentioned before, I used my house as scaffolding to apply the goop using a long paint roller. That made the job fairly doable. However, the weather down here was being a total jerk. Normally, we have sunny skies most of the time. But no, not on the days when I had to paint... ON TWO SEPARATE OCCASIONS I went out to a clear-blue morning, put a coat of rubber roof coating on (which needs a few days to dry), and had the sky fill with clouds and dump rain on it in the afternoon. That made me mad. Can you tell I'm mad?

>:(

There. That's how mad I was. And sort of still am. The roof coating stayed on mostly, at least on the sides. The top got washed off though and had to be re-applied. Also water got in between the coat and the walls and lifted it gently. I now have a very odd wrinkle pattern on the side where the water got in. It seems to be stuck down quite well now though. but I ended up needing a second bucket to finish because of this. Why the long story? I don't know, it's actually kind of funny to me now, and if your roof coating does get wet, you can know that it won't ruin everything!

I decided to coat the inside as well, including the floor. Originally I was just going to use it to coat a shower stall, but I realized if I coated all of it I could just hose the whole thing out when dirty. It dries awfully slow inside though, so plan for that if it's the route you pick!

NOTE: Before going inside, you'll have to place jack stands at all of the corners, or you'll be in for a wild ride! A larger trailer might mitigate this, but those of us with small trailers will need support. To set them up, I just place them where I want them, and lift. I pull the top of it into the wood, lifting it all slightly, and wait for the "click." If one side won't quite "click," lifting the other side usually tilts it over to where it sits fine on the stand.

Protip: An alternate method you can use if you have a tongue jack on your trailer is to get the trailer to sit with a slight forward tilt, and raise the rear stands to touch the back two corners. Then use the tongue jack to tilt the trailer slightly backwards. Place the front two stands, and use the jack to drop the trailer onto them. I often use this method if the trailer is fully loaded and I don't have the "oomph" to lift everything inside. Every once in awhile though, I have to move the rear stands around a little bit or the door won't close properly. Sometimes I only place just one jack stand in the center to avoid that issue. I recommend playing around with it to get a feel for it.

A final tip - the "as seen on TV" Flex Seal product works great for hard to reach areas or touch ups. A little spritz here and there was used. It's sorta pricey but also useful. I never tried spraying it on wet roof coating though, so let that dry first to be sure.

Whew. That was a lot of work. What came of it?

Well. At this point if you've read this far you probably have one of two thoughts. Either "Wow that's so cool!" or "Wow that's so insane!"

Both are fine with me honestly.

What are my thoughts? Both. This thing is a bit too tall and looks quite silly. It's also made out of foam and meant for freeway use. That's CRAZY. But it works wonderfully, it's a lot of fun, and I'm glad I did it! Its maiden voyage (beyond simple freeway tests) was to AZ/NM Decompression. It made it all the way without any issues!

Okay, you said it looks silly. And that it is insane. And I agree. So why in my right mind would I build one???

Adventure. Fun. Challenge. Utility. Humor. Uniqueness. Frugality. Innovation.

Adventure. This build, for me, was an adventure. All of the little challenges along the way that popped up. All of the problems that needed solving. How was I going to hold the foam to the plywood? How was I going to paint the roof? And would it even work on the road? Or would the wind rip it to shreds past 45 mph? I for one have not seen anything quite like this, and the structural data of the materials was a bit lacking. So were drag coefficients for a shape like this. So I couldn't be certain it was going to work. All of that together made this such a grand adventure! And the uncertainty made it a bit of a scary adventure... but when everything is working out and when things are looking up - that kind of scary also be fun!

Fun. This was A TON OF FUN! When I first told people that I was going to build a foam camper they thought I was nuts. I thought maybe that was the case, but I pushed forward anyhow. Then came all of the problems to solve along the way... Personally, I take great joy in solving problems! So that part was fun too! Even the particularly annoying problems often turn into great stories - like the epic battle between our odd weather system and my paint. It worked out in the end, and in retrospect it was pretty funny. While problem solving has it's own rewards, each time a major step was completed I felt a huge sense of pride! Things were coming together! Finally, upon completion, I felt a huge sense of elation! I got a second dose of that as well once the road tests were completed. But the fun didn't stop there - the maiden voyage was its own special experience. I rather enjoyed the look on people's faces when we rolled through a gas station with this thing in tow. Sometimes we got questions - "What is that?" seemed to be most prevalent. Occasionally someone would recognize the Harbor Freight trailer underneath, or the foam panel exterior. Those folks often had some insightful commentary, and it was fun to shoot the breeze with them for a few moments while Scooby had a meal. Then, when we got to our first burn with it - AZ/NM Decompression - people immediately noticed that someone had put a yurt on wheels. Even in the middle of the night, we ended up with a small crowd of people who mainly just wanted to see what it looked like inside. A few of them said it looked awfully warm inside at night (which it was!) and a lot of them just wanted to know how it was done (if you are reading, this is for you guys). Either way, it was an instant conversation starter! Oh yeah, it's also fun to go camping :P And this project allows one to set up their camp with a lot less challenge than normal (minus initial investment of course).

Challenge. This was indeed a challenge. Not everyone builds their own Camper trailer. Especially not out of foam panels! But it's a good challenge, I think. I learned a lot, and in the end I was able to make my camping experience a lot easier! And you can too! Sure, it takes a bit of work ahead of time, but it's good work. Using your bare hands and creativity to put a roof over your head wherever you might want to go. And making that experience much more comfortable with whatever utilities you'd like to build in!.

Utility. Man, this thing is as useful as a camper trailer. Because, well, yes. I concede that it's a camper trailer basically. Or an RV, if you prefer to call it that. You can haul (as seen here) 42 gallons of water and have it come from a faucet or shower (or whatever you want) inside. You can stay cool in direct sunlight or warm in the cold night. You can add a hot-water heater (upcoming post, I promise) and take warm showers on a chilly day. But it's also ridiculously light. You can push it around with one hand to put it away. You can tow it with a sedan. And you can power the whole mess with a single solar panel. How cool is that? We'll go over our goals list at the end and see how we did, but I think we met them all! Even though some of them were quite humorous.

Humor. This also works under the fun category. I guarantee if you start talking about making a camper out of foam panels, you'll get some laughs. I know I did. Even from folks why fly foam aircraft with me. On the surface this just seems like... a silly idea. And it looks silly too, as we've discussed. But it's awful fun to own it. To point at it, smile, and say "Yeah, I did that. I did that even though it seems like a bad idea. Even though every instinct in a sane person's mind screams not to... I did it anyway." And the punchline is that it worked. It worked, and it is unique because there's nothing else like it! At least not yet anyway...

Uniqueness. As far as I know, at the time of this writing, I have the only one of these in existence. That means they are rare.[16]*citation needed* Even if 1000 people build them exactly the same, they'd still be rare. But 1000 people won't build them exactly the same. Because there is no set way to do this! Each one would be unique. A reflection of the builder. People can say "Oh no, that's not the right spot for the shower," and fix it as they saw fit. Perhaps someone else wants a different shape. Something taller. Something shorter. Some cute windows perhaps. The point is, if you build one, it's a reflection of you. And if you don't like what you build, the materials are cheap enough to reconfigure even for the most frugal of us.

Frugality. You could probably buy a used camper trailer for the cost of building one of these things. I'll be honest about that. But you'd need to shop around, and you'd probably end up with one of the pop-up tent ones. Also you may not have running water. You'd also have some maintenance to do to get it ready, which also costs money. If you wanted to keep cool you would need a generator - another thing that costs money and requires maintenance. The costs add up pretty fast is my point. And when you chalk up all of the features you get (and more as well if you are a clever devil, which I'm sure you are), you start to find that it can't be beat in price. And because this is open-source I'm sure we will see some cost improvements with folks' various innovation.

Innovation. This project is a blank slate. It even looks like one! At least mine does. It really is just an empty box with whatever you want inside. Sure, I mention running water and showers and things, and I give some very basic pointers here of how to do that (detailed instructions coming soon though). But if you end here and open your mind up to the possibilities - what do YOU want to put inside? How can you improve this? What's important to you? Maybe find a safe way to run a kitchen inside? Maybe add a lifted bed to the mix for more floor space? Maybe do something different entirely! Perhaps someone could use these basic ideas to build a micro yurt using the motorcycle trailer that Harbor Freight sells. Then they could tow sleeping quarters behind their bike on a long road trip! How cool would that be? Take it. Form it. Make it yours.

I don't know if I've convinced anyone, but then again I don't feel the need to. It's a thing that anyone can choose to have, or choose to not have. But, we did have a list of goals - so let's see how we did!

If you still wish to use a tote, here's how I installed mine. I cut a hole and installed a drain fitting into the bottom using some shoe-goo. Then, I hung it with straps as I did the freshwater tanks. I didn't use a plywood bottom for the tote though since it sat a bit higher up than the others. Later on I joined some 3/4" irrigation tubing together from the various drains in my floor, and plumbed them to the tank. I left a hose bib and cap on there to drain it to my evaporation pond. One thing I did learn however is that I should have used a larger diameter pipe to get water to and from it, as the 3/4" tube got plugged by the residue left in it while it sat for a few months. I'll likely summarize a good solution in the next post, but I have to figure that out first. Meanwhile I just blast the drain out with the hose to prep for a trip.

As for the swamp cooler, I screwed lid to some strapping, and added shoe goo to keep it stuck. The latches on this tote are capable of holding it tightly to the lid without any support. I put a drain plug in the bottom so I never have to travel with any water in it (which might break the latches). The tote is filled through a float valve, so it only ever gets a few inches of water in it anyhow. So far so good. I'm sure there are even more clever ways to do this stuff, and I hope to see some folks being inventive! I'll briefly describe the principles behind swamp coolers next, but I will leave the full design specs for a later post (as I'm still tweaking things a bit). Feel free to skip the next box if you don't need to know about swamp coolers.

| Swamp Cooler Box... Box Swamp coolers are simple. You can make one from a box! They work by evaporating water to cool the surrounding air. Its the way your sweat works! A good way to evaporate water is to have a lot of surface area between the water and the air. This is often accomplished by trickling the water through a cooler pad made of paper or wood shavings. Whatever material they are made of, these pads have a lot of interesting shapes for the water to flow along. They are also very porous, to allow air to pass through and to allow the water be surrounded by as much air as possible. This is a great first step in evaporation! However if the surrounding air isn't moving, it quickly becomes saturated (humid) and stops allowing new water molecules to hang out inside. Because air absorbs water fastest when it is driest (that's why these things work terribly when it's humid out) a fan is used to move air through the cooler pad, providing lots of fresh air to infuse with water and a nice cool breeze for you! So how do you make a swamp cooler? I started with a plastic tote, and used some PVC with the ends plugged and holes in the side to trickle water downward through a cooler pad. I held this pad on to the PVC with zipties. Because of gravity, the water collects in the bottom of the tote, and I cycle it back up to the PVC pipe using a small 12v water pump. To provide airflow, I used the blower in the BOM to push air through a hole in the upper side of the tote. The top of that tote seals relatively well, so this setup works without leaking too much air. You will be able to see the fan and tote in the next picture. What you can't see is that I have a hole on the opposite side of the pad from the fan, and I use dryer duct to route the cool air exiting that hole into the yurt. That's the basic idea for swamp cooling. It uses little power and little water and can cool a yurt in the hot desert as long as it's dry outside. I'll go into it in more detail when I polish my design more and when I write the concluding post regarding the fine amenities that one can build into these yurts (or any tents or structures if you want I suppose). |

|

| Utilities installed. |

At this point, your creation needs a floor. All that stuff so far is pretty neat for sure, but it's useless without a floor. There are far too many holes, and nothing looks comfy to sleep on. Plus, you need SOMETHING to hold up the walls. So the next step is to build a floor. At least I think so.

How big of a floor can you make? The laws around here say you can't have a trailer more than 8' 6" wide. So there's an upper boundary. I've built a few 6' stretch hexayurts, but they are only about 7 feet across.[8] Source: http://www.appropedia.org/Hexayurt_playa For my personal yurt, I decided to go big or go home.[9]Ironically I did both since I was building a "go home."

Source: It is a home that goes. And it is big.*

*Does that mean I go big or go home with my big go home?

My my... How meta, once again. I decided on 8 feet wide, since that's the width of standard plywood sheets (and also to err on the side of caution). The length of the 6' stretch is appropriate for the trailer, so I decided to keep it. Below is the floor plan.

|

| Created in Fusion 360. |

You can build this floor out of three sheets of 4' x 8' plywood. You only need to cut the corners off of two sheets as seen below.

|

| 3.464 feet is about 3' 5.5 inches. |

I screwed the three pieces of plywood together to two 8' 2 x 4's, one on the left and one on the right. That held the whole mess together to work with. Next, I screwed a 12' 2 x 4 in the center to add a bit more support. Finally, I slid a 10' 2 x 4 on each side and screwed them on in-between the 8' and 12' boards. Together, these created the longitudinal support for the floor.

For lateral support, I used 8' 2 x 4's. I screwed them underneath the longitudinal boards to match the spacing of the boards on the trailer. This was needed for two reasons: One - I needed a bit of extra height to clear the fenders. And two - I wanted to be able to lift the entire yurt off of the trailer, if the need arose. The completed and installed floor is below. Again, apologies for not having pictures of the underside.

|

| Suddenly, the trailer could be used for something again. |

IMPORTANT NOTE: Before you climb onto your new floor you'll need to support the edges and rear with jack stands or something equivalent at this point. The structure will be sturdy, but sturdy won't stop it from tipping over! You've been warned!

Now that you have a floor, you'll need to add a border that's offset by the width of your RMax foam. I used 1.5" foam, and as such I measured and cut my boards accordingly. In addition, you'll want to decide if you want to make a shower stall, or add any ventilation. You can form the shower stall from 2 x 4's, and the ventilation from a hole.

Below is what my floor plan looks like. I put the door in the back so the so wind wouldn't screw with it while driving. Then, I made the decision to put the shower in the back near the door because if I was filthy and needed a shower, I didn't want to crawl over my clean bed to get to it. Another consideration is that we planned to keep a camp toilet in the shower stall, so popping in from outside to use it would be more convenient that way.

|

| What a mess. But it was coming together! |

|

| Ventilation for the swamp cooler. |

The next step was to put on walls. A floor isn't completely useless without walls however. At this point you might be able to bring your sick dance moves to the floor! You've never danced like this before![10]Source: Milky chance. Except for the fact you put all of those 2 x 4s on top of it to trip up your dancers. Pity. Oh well, let's just keep going then.

The 6' stretch yurts I've built have 4' walls on the sides. This gives standing room in the very center, but just barely! Since I was going big, I wanted to be able to stand up in the thing. And also wave my arms around when changing clothes At Burning Man I have seen some of the tall yurts (with 8 foot walls). I think those are a little bit too tall, but I understand why they are built that way. The foam panels come in 4' x 8' sheets, so 8' is a natural height.

But what we are doing isn't natural, is it?

I was worried about drag while I towed this thing. I also needed a few 1' 0.86"[11]Still an unclean mess of a dimension.

Source: Ewww. strips to widen the classic 6' stretch design to 8 feet. I figured I'd cut those off the edges of the wall panels, and shorten the walls. Because I was cutting the walls down anyway, I decided to shorten it further to reduce drag.[12]Less height = less area, and since drag is

proportional to area, less area yields less drag. I chose 6 foot tall walls. Why? It sounded good at the time and gave me a decent door height. Would I do it differently if I did it over again? Yes. I'd probably cut them down to 5 feet to reduce drag a little more. But hindsight is 20/20, and my yurt is built and I'm not changing it at this point. So that's how these instructions will proceed. Feel free to work out your own design though!

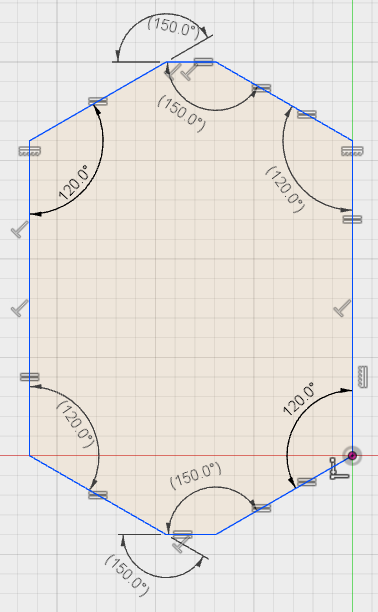

After you decide on your height, cut all of your wall panels (if you are following my exact design, 8 full wall panels and two narrow ones) to whatever height you decided on. Next, you'll want to miter them to fit together a bit better. That means you'll want to angle the corners so that the panels meet at the appropriate angles. This is quick to do with a circular saw, but makes lots of foam dust. Below are the angles for the walls using the 6' stretch base with a thin panel in the middle:

|

| You'll want to cut each panel equally, so the sum of the two joints adds up to what is seen here. |

After that, pick one panel to cut a door. Unless you never ever want to go inside. Actually, you'll need to get inside to put the roof on. Unless you don't want a roof. Who am I to judge? I used the right rear panel. I won't judge you if you use a different one. Unless you use THAT one. Geez...

Anyhow cut your door to whatever shape you wish. I spaced mine 6" from the edge of the panel, and used 90 degree corners. Perhaps I was under the false impression that it was hip to be square. I don't know. You can make it round if you like. Or even jaggedy. Whatever you choose, make sure it's feasible. Then cut it out, and reinforce the edges with some bifilament tape. The door will create a fairly large stress riser.[13]This means the door causes the forces to multiply

due to the cutout made for it, and will need to be

reinforced as such. I also recommend reinforcing the edge of the door itself, so the foam doesn't crumble. You may be able to get away with just using tape for this (I have done so on other yurts, but never with a door this tall). For mine, I used some roof-edging to create a door frame. I cut and bent it at 90 degrees to form corners. Then, I just taped that stuff on. You may need to cut some strips off the door to make sure it fits back in the hole once all the extra tape and things are added though. Experiment before you finalize! Also at this point you'll be covered in magical foam dust anyway[14]Source. so what's a little bit more of the stuff?

Once the door fits, use tape to form a hinge. I hinged mine on the outside, and have it opening away from center. That way if it flies open on the road, the wind shouldn't tear it off. At least not right away. I honestly don't know how I'd find out if it was flapping around on the road. So whatever you do make sure it closes well!

Protip: For a MUCH STRONGER hinge, slit about 12 inches inward from the top and bottom of your hinge tape. Then create "barn door" hinges at the top and bottom using overlapped tape. I could explain it, but here's a great simple example using masking tape. This will prevent the tape from peeling away when the door is open. You should be able to feel the strength difference immediately upon doing the modification, but the basic idea is that it causes the tape to be loaded in tensile force instead of peeling force. This is much better since tape holds up best to tension, and worst to peeling forces.[15]Source: This is why we peel it off instead of

ripping it off in a straight line with our teeth.

To close the door, I used the cabinet latch system seen in the BOM. I had to cut the posts down a little bit, but the metal was super soft and easy to cut and file into a pointy shape. I used some more of the sheet metal to create hard points for the door posts to stick into, and taped those on. Then I drilled appropriate holes for the top and bottom posts, and also cut a slot for the side latch. I mirrored this effort on the door itself, and cut channels in the foam to slide it into. Pieces of ducting sheet metal and tape were used after installation to keep the structural integrity. I wish I had taken pictures of this step, as it was fairly easy to do, but sort of hard to explain. Apologies. Also the latch system I used does not appear to be available anymore, so you may have to improvise here. Apologies again.

You may also wish to use a different system, or even a basic doorknob. Another idea would be to build a wooden door frame, and maybe even add a (lightweight) wooden door for extra security! Since my door was made of foam, I was initially thinking I needed the three-point latching system to keep it shut on the road, but now I'm not so sure that's the case. I got an idea from James Lewis on Facebook to use velcro tabs to hold a yurt together - perhaps velcro tabs could be used for the closing mechanism! There are lots of potential possibilities, and more people might have even more ideas. Besides, without the three-point system I could have cut a round top to my door, which would have been both strong (smaller stress risers) and cute. Take heed, fair reader, for you have powers that I did not! Use them for good and never eeeeeeeevil!

Wow, that was dramatic. I guess maybe I'm being dramatic because I didn't take any other pictures of the door latching mechanism. It's a great distraction! But also not as interesting as pictures. So let's complete this thing and then look at pictures, shall we?

Before setting up the panels, I recommend covering all outside-exposed bifilament tape with aluminum tape at this point. The filament tape will get eaten by the sun. The aluminum tape will laugh at the sun. Well, it probably won't actually laugh. If it does, put your tools away and continue the project when you are sober.

Now you are ready to put up your walls! I'd wait for a calm day, or get a lot of help. But you can struggle as you see fit. I managed to put mine up on a windy day and only got help to hold one panel up. The trick was to get angled just right so the wind helped hold things together. Regardless of how you do it, stand the walls up and tape them together using bifilament tape. Then go over the edges with some aluminum tape.

Whew! Walls are up! Great! You can tape the walls to the plywood underneath, but the bifilament tape doesn't stick super wonderfully to the wood in my experience. You'll either need a secondary adhesive (3M #77 works) or just use aluminum tape.

Protip: Plan out the timing so that you get all of your tape covered with aluminum before you quit for more than a day. That bifilament tape gets yellow very quickly in the sun, and it would be terrible to put in a bunch of work and have it start to deteriorate. You'll need some decent lighting to get it right too, so watch the clock!

You might be tempted to tape the inside joints at this point, but I recommend against it. At least for now. For a stronger joint I glued the panels together by squirting in some "Great Stuff" which is an expanding foam insulation. I think it is also the same stuff in the RMax foam panels. However it expands a LOT, so before injecting any of it, I decided I should have everything secured as best I could. I think you should wait on it as well, so as not to blow everything apart!

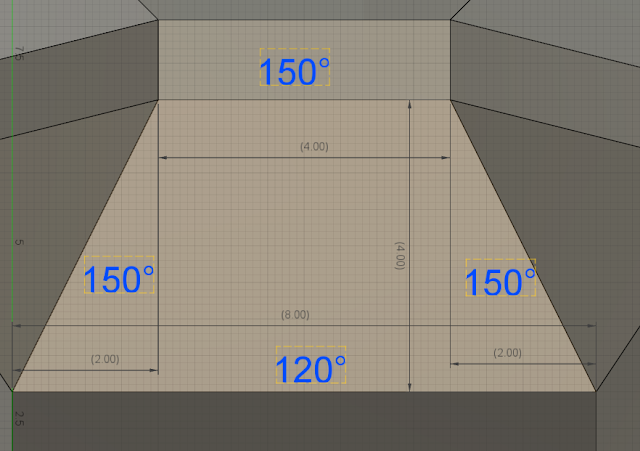

Therefore the next step, in my humble opinion, would be to put the roof on. Below are the panel dimensions and miter angles for them. You can make some extra triangles by taping the parts removed to make the trapezoidal pieces together along the 4' edge.

I think the easiest way is to build the roof on the ground, and lift it up with a helper when it is done. My recommendation is that you start by taping everything together as seen below:

Anyhow cut your door to whatever shape you wish. I spaced mine 6" from the edge of the panel, and used 90 degree corners. Perhaps I was under the false impression that it was hip to be square. I don't know. You can make it round if you like. Or even jaggedy. Whatever you choose, make sure it's feasible. Then cut it out, and reinforce the edges with some bifilament tape. The door will create a fairly large stress riser.[13]This means the door causes the forces to multiply

due to the cutout made for it, and will need to be

reinforced as such. I also recommend reinforcing the edge of the door itself, so the foam doesn't crumble. You may be able to get away with just using tape for this (I have done so on other yurts, but never with a door this tall). For mine, I used some roof-edging to create a door frame. I cut and bent it at 90 degrees to form corners. Then, I just taped that stuff on. You may need to cut some strips off the door to make sure it fits back in the hole once all the extra tape and things are added though. Experiment before you finalize! Also at this point you'll be covered in magical foam dust anyway[14]Source. so what's a little bit more of the stuff?

Once the door fits, use tape to form a hinge. I hinged mine on the outside, and have it opening away from center. That way if it flies open on the road, the wind shouldn't tear it off. At least not right away. I honestly don't know how I'd find out if it was flapping around on the road. So whatever you do make sure it closes well!

Protip: For a MUCH STRONGER hinge, slit about 12 inches inward from the top and bottom of your hinge tape. Then create "barn door" hinges at the top and bottom using overlapped tape. I could explain it, but here's a great simple example using masking tape. This will prevent the tape from peeling away when the door is open. You should be able to feel the strength difference immediately upon doing the modification, but the basic idea is that it causes the tape to be loaded in tensile force instead of peeling force. This is much better since tape holds up best to tension, and worst to peeling forces.[15]Source: This is why we peel it off instead of

ripping it off in a straight line with our teeth.

To close the door, I used the cabinet latch system seen in the BOM. I had to cut the posts down a little bit, but the metal was super soft and easy to cut and file into a pointy shape. I used some more of the sheet metal to create hard points for the door posts to stick into, and taped those on. Then I drilled appropriate holes for the top and bottom posts, and also cut a slot for the side latch. I mirrored this effort on the door itself, and cut channels in the foam to slide it into. Pieces of ducting sheet metal and tape were used after installation to keep the structural integrity. I wish I had taken pictures of this step, as it was fairly easy to do, but sort of hard to explain. Apologies. Also the latch system I used does not appear to be available anymore, so you may have to improvise here. Apologies again.

You may also wish to use a different system, or even a basic doorknob. Another idea would be to build a wooden door frame, and maybe even add a (lightweight) wooden door for extra security! Since my door was made of foam, I was initially thinking I needed the three-point latching system to keep it shut on the road, but now I'm not so sure that's the case. I got an idea from James Lewis on Facebook to use velcro tabs to hold a yurt together - perhaps velcro tabs could be used for the closing mechanism! There are lots of potential possibilities, and more people might have even more ideas. Besides, without the three-point system I could have cut a round top to my door, which would have been both strong (smaller stress risers) and cute. Take heed, fair reader, for you have powers that I did not! Use them for good and never eeeeeeeevil!

Wow, that was dramatic. I guess maybe I'm being dramatic because I didn't take any other pictures of the door latching mechanism. It's a great distraction! But also not as interesting as pictures. So let's complete this thing and then look at pictures, shall we?

Before setting up the panels, I recommend covering all outside-exposed bifilament tape with aluminum tape at this point. The filament tape will get eaten by the sun. The aluminum tape will laugh at the sun. Well, it probably won't actually laugh. If it does, put your tools away and continue the project when you are sober.

Now you are ready to put up your walls! I'd wait for a calm day, or get a lot of help. But you can struggle as you see fit. I managed to put mine up on a windy day and only got help to hold one panel up. The trick was to get angled just right so the wind helped hold things together. Regardless of how you do it, stand the walls up and tape them together using bifilament tape. Then go over the edges with some aluminum tape.

|

| This was prior to covering the bifilament tape. |

|

| Here is where I began to suspect it might be too tall... |

Whew! Walls are up! Great! You can tape the walls to the plywood underneath, but the bifilament tape doesn't stick super wonderfully to the wood in my experience. You'll either need a secondary adhesive (3M #77 works) or just use aluminum tape.

Protip: Plan out the timing so that you get all of your tape covered with aluminum before you quit for more than a day. That bifilament tape gets yellow very quickly in the sun, and it would be terrible to put in a bunch of work and have it start to deteriorate. You'll need some decent lighting to get it right too, so watch the clock!

You might be tempted to tape the inside joints at this point, but I recommend against it. At least for now. For a stronger joint I glued the panels together by squirting in some "Great Stuff" which is an expanding foam insulation. I think it is also the same stuff in the RMax foam panels. However it expands a LOT, so before injecting any of it, I decided I should have everything secured as best I could. I think you should wait on it as well, so as not to blow everything apart!

Therefore the next step, in my humble opinion, would be to put the roof on. Below are the panel dimensions and miter angles for them. You can make some extra triangles by taping the parts removed to make the trapezoidal pieces together along the 4' edge.

|

| Trapezoidal panel dimensions and angles. |

|

| Triangle panel dimensions and angles. |

|

| Sloping roof rectangular panel |

|

| Roof rectangular panel (top) |

I think the easiest way is to build the roof on the ground, and lift it up with a helper when it is done. My recommendation is that you start by taping everything together as seen below:

|

| The bottom right triangle was constructed from two of the pieces cut off of the trapezoid. You can see the aluminum tape covering the joint. |

Once you get that built and taped, lift it up onto your walls. It should be light, and without wind you may not even need help. But help is good, so find it if you can. Pay your help in tasty food or beer. That last part is optional, but always appreciated I'm sure.

Once the roof was on the walls, the hard part was getting the tape on since I had to keep moving the ladder. If I did it again I might use the house as scaffolding to tape the roof on. If you do that and it works, great! JUST BE SUPER CAREFUL!

|

| Thankfully it wasn't getting any taller after this. |

Okay, did you get the tape covered? All good. Sweet. You can rejoice some! I rejoiced by repeatedly going in and out of the yurt. Then going inside and feeling like something neat had happened. Then going back outside and going in and out again. In retrospect it wasn't the greatest evening, but it sure felt good at the time. Still, there was more work to be done!

If you planned to take this on the road, as I did, you may be wondering what was going to keep all of that foam firmly attached to the trailer. After all, the tape didn't stick as to the wood as well as one would have liked. Additionally, roads are bumpy. I'd wager the different materials (foam and wood) would flex differently due to their differing weights and elastic properties. That flexing would make them inclined to separate from each other...

Separation would be bad. Though it would also be an awesome sight to see one of these come apart at 75 mph, it would also just be very bad. We don't want bad. Fortunately there's a simple solution! Grab your pipe strapping, and run three strips over your yurt (more if you have a different design that requires it). I did one longitudinally and two laterally. You'll see in the picture below. I also cut some squares from cheap ductwork sheet metal, and placed that underneath the straps where they went around the corners. This was to spread the load out so the strap didn't end up cutting into the foam. I held the sheet metal on using 3M spray adhesive just long enough to tighten the straps on. Again, this can be seen below:

|

| My goodness, what a strapping yurt! |

Here is the method I used to get the straps on there with just the right amount of tension. First, I attached one end to a 2 x 4 using a deck screw installed at about 45 degrees. I left about 3/4" of thread length out. Then I tossed the strap roll over and pulled it tight with my bare hands. I added another screw at 45 degrees to the opposite side, but this time screwed it all the way in. The 45 degree angle caused the strap to tighten as the screw pulled in! Then, I went back to the other side and tightened the first screw carefully, and listened for crunching foam sounds. I heard no crunching, so this method seemed to work great! I ended up with a very tight strap and nothing getting crushed. Success! I added an extra deck screw straight in at each side for good measure (there are lots of holes to work with).

At this point I covered all of the straps with aluminum tape, to keep them from oxidizing mainly. I'm not sure if it was needed since I rubber-roof-coated everything, but at the time I was considering running it without the paint.

To install the optional roof vent (which will improve swamp cooler performance when your door is shut), I used 3M spray and some bifilament tape. I didn't cut the hole right away. I just stuck it on where I wanted it with the spray, and then taped it. After taping, I covered the bifilament tape with aluminum tape to protect it from the sun. Next, I measured where the center of the vent would be, went inside, and stabbed upward with a knife. So fierce. Then I sawed my way over to where the knife hit the roof vent. Next, I used the vent as a guide for the knife and ended up with quite a nice ellipse shape, just as expected. I finished the inside with some aluminum tape to keep the foam from crumbling and called that good.

At this time I decided to squirt some "Great Stuff" in the inner cracks of the panels (as mentioned earlier). This glues them together and creates a stronger joint. It also expands and provides a bit of tension to hold everything tight without wiggling. Keep in mind though, that it can expand and force your panels apart, so don't overdo it! I put a little in all of the gaps, more if there was a larger than normal gap, less if it was tight. I also did the gaps between the 2 x 4s on the inside and the foam panels.

Once the "Great Stuff" has dried, you'll probably want to cut off the lumps that squirt out. You can try to wipe it off as it initially squirts out, but you may come back and find even more of it. However you do it, you'll want to get rid of the lumps. Then you can add some bifilament tape on the inside for greater strength. I haven't felt the need to cover up the inside tape with aluminum tape since very little sunlight gets in there. So far, so good!

Before doing anything else, I wanted to test this thing on the road. The first steps were around the neighborhood, with a 25 mph speed limit. The next step was on the two lane road near my neighborhood, with a speed limit of 45. After each step I pulled over safely and looked it over. I was pleased to see nothing coming apart, but I resolved to wait until the next day for freeway tests. In the morning, I took it to the gas station and filled up. Then I took it on a segment of the freeway that had a 55 mph post. Since nothing went wrong, I continued to the 65 mph zone, and followed that to an area with a 75 mph posting. I was able to get Scooby (the Subaru Forester) up to 75, but just barely. He was really huffing at that speed! 65 is a much nicer cruising speed. I averaged 65 over the return trip to the gas station where I filled up and figured out my mileage. About 14 mpg. Not great, but not horrible. In it's prior configuration the trailer pulled me down to 17 mpg. It had a LOT less frontal area, so I'd say the shape of this yurt is reasonably aerodynamic for its size! Woo!

Below are some pics of the nighttime road test.

|

| No damage! |

|

| It looks just marvelously ridiculous! |

At this point, I coated both the inside AND the outside with rubberized roof coating.

So why not just run it naked? Woo! Naked!

Two reasons. The first is simple. Itt actually strengthens the foam a little bit, and allows it to deflect small rocks and bugs a lot better than the foil would by itself. The rubber coating doesn't tear quite as easily as the foil so things bounce off it more.

The second reason is longevity. On the playa if any tape started to peel, we'd see it and fix it. If this thing were to sit in my yard for a few months (which it does) and some tape started to peel, would I notice in time? The answer to that is most likely, no. And if I didn't, rain and dust would get under it and really start to mess things up. Then I'd have a ton of repairs to do before taking another trip. So I looked into the cheapest and most weather-tight way to seal everything up and keep the tape down. The roof coating seemed to be it. Also the reflective and radiant properties of the rubber roof coat match the aluminum of the insulation, so no performance degradation should be seen!

Great! But are there other options?

Yes, but they are EXPENSIVE. At least the ones I found. I'm open to suggestion though and will cite you here if you have anything that looks good! As for me, I looked into fiberglassing the whole thing. That would be wicked strong. But sorta pricey. I think I could do it for $600 to $800, but then I'd need a coat of paint to protect the resin anyhow, which leads us back to square one basically. Also a thin layer of fiberglass might be brittle and start to crack. So we'd need a thicker coat. But more fiberglass costs more money, and uses more resin. More resin also costs more money. I wanted this to be accessible to everyone. So "more more" money was sort of out of the question. But if you have the money and the skills, 'glass that sucka! Then paint it a nice fun (hopefully light) color!

Okay fine, but can't we get by without using the aluminum tape then? It's really a pain to put on. What if I plan everything out and paint over it right away before the bifilament tape gets any sun?